The Crookston High School Fabrication and Welding I class and their teacher, Travis Oliver will be on Focus on Education this Saturday morning, who have completed one of their major projects for the semester. The class was tasked with taking a raw, flat piece of metal and use the tools and machines provided to them to create their own custom, self-designed toolboxes.

The 10th-12th grade class consists of Seniors Issac Wandrie, and Samuel Stewart, Juniors Jaren Bailey, Ethan Boll, and Jackson Demarais, and Sophomores, Jamie Brown, Chase Proulx, Evin Trudeau, Edward Luckow, Wyatt Wilkens, Javen Lund, Koda Donarski, and Ty Larson. The project had many different components they had to create that brought together all of the skills they had learned in the class up to this point, such as design, their handiness with the tools and machines, and creativity with the materials they were given. They had to cut the metal with the plasma cutter, weld up all the corners, grind and polish the metal, come up with a solution to open and close the lid and make a handle on the top. “All of the students came up with their own ideas, which is what one of my goals is,” Instructor Travis Oliver explained, “For the students to Critically Think and go through that process of designing and then move on to bigger and better things.” For many of the students, it was their first time using these machines without any guidance. Many of the materials that the students used were similar to one another, but each student had their own twists to their boxes to make them unique from everyday toolboxes.

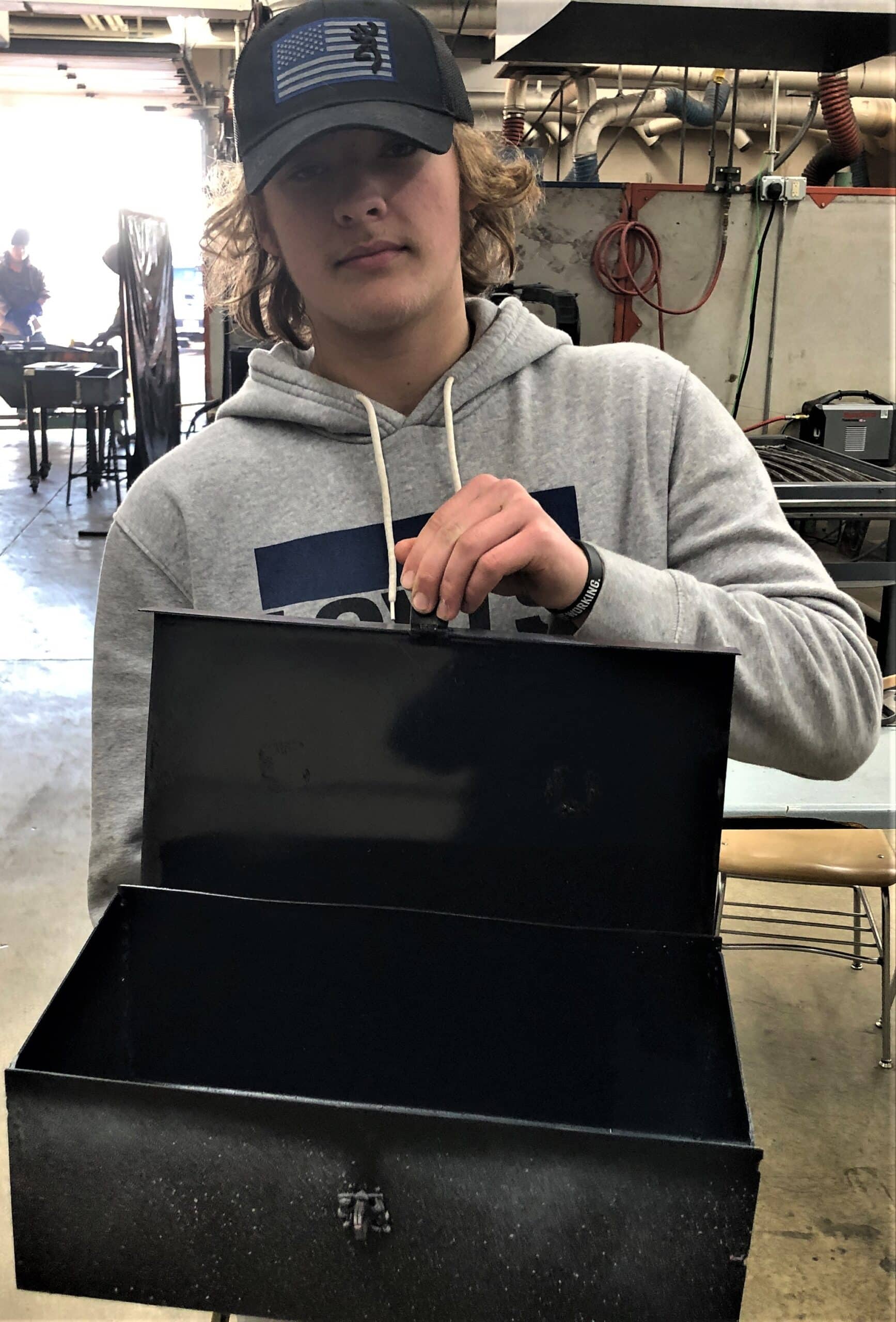

Such as Junior Jaren Bailey, who bent and welded a scarp rebar to the lid of the box and used a magnet to help line it up to be welded in the center of the box and some angle iron around the perimeter to help it close and smooth the edges out (flushed). Junior Ethan Boll created a unique painting design for the box’s exterior and added a small separate compartment to store nuts, bolts, and shells inside the box. Sophomore Chase Proulx added thin door hinges to open his lid and bent a quarter-inch bar to make it easy to pick up even if someone is wearing work gloves, as well as a lock mechanism to protect anything put in it from being stolen or damaged. Sophomore Jamie Brown took a more colorful approach to his box, spray painting the inside of his box blue with a large face on the bottom. Sophomores Ed Luckrow and Ty Larson chose different materials for opening their boxes, choosing latches on the sides of the boxes to keep them closed rather than a door. Sophomore Wyatt Wilkens and Junior Jackson Demarais created their box’s handles with even more unique materials, welding segments of steel chains together to keep them stiff enough to be the handle.

While most students had completed their projects, a handful still have some major steps to complete or some finishing touches to add to complete their project.

Instructor Travis Oliver was very pleased with the student’s projects, believing that they have learned a vital lesson in construction and working with certain materials and expectations. “I think they did a good job. It’s a process, and that process changes as you’re figuring stuff out. Trying to fabricate something out of nothing is not something everyone can do as you do it and do it well; you get better at it. You potentially create a job for yourself, and people are still looking for those types of people.” Oliver explained, “So if you enjoy doing that kind of thing, taking the raw material, and making a finished product, whether it’s a toolbox or something much bigger like a Bobcat or a tractor for Case or John Deere. The engineering and fabrication behind it, all those things are getting built on a yearly basis. So the first step is learning how to use certain things, and you can’t start on a large scale. You have to start on a much smaller scale, in my opinion, so that’s one of the steps behind it.” Oliver continued with how the projects he’s conducted with the class will help them learn the process of working with clients and trying new ideas in the middle of projects. Similar to how contractors and construction companies work with clients. “They’re doing a good job of going through the process of problem-solving and critical thinking, like “Well that didn’t work, let’s try this,” or “Oh we have to redesign this,” or “We have to look back at square one,” where if you think of the school as the customer, and we’re trying to please the customer and build what the customer wants.” Oliver explained, “The first time you do stuff like that doesn’t always work out the way you drew it up on the computer. And that’s the process, it’s never going to be cut and dry. There will always be people making decisions differently and having different ideas in the middle of a build. So, I think they’re getting a good experience with it,” Oliver also explained that there are still many projects the class is creating for the school and the City of Crookston. Including an entrance tabletop at the Golden Link made by a student whose mother works there and a new desk at the front of the school for admissions. Others are being kept secret until the class begins them.

Pictures of the students and their toolboxes can be found down below, showcasing each one’s uniqueness. To learn more about each student’s thought process and challenges for their projects, listen to Focus on Education on Saturday at 8:35 a.m. on KROX.