Continuing our story on Vertical Malt, Adam Wagner, President of Vertical Malt, hopes the business will be able to break ground on a new malt house by 2020. “We’re working hard on the plan right now, trying to get the footprint that we know we’re going to need,” said Wagner. “It’s possible we could break ground in 2019, more realistically it will be sometime early 2020. Hopefully as soon as the ground thaws in the spring next year we’ll be putting shovels in the ground and trying to get that facility built.”

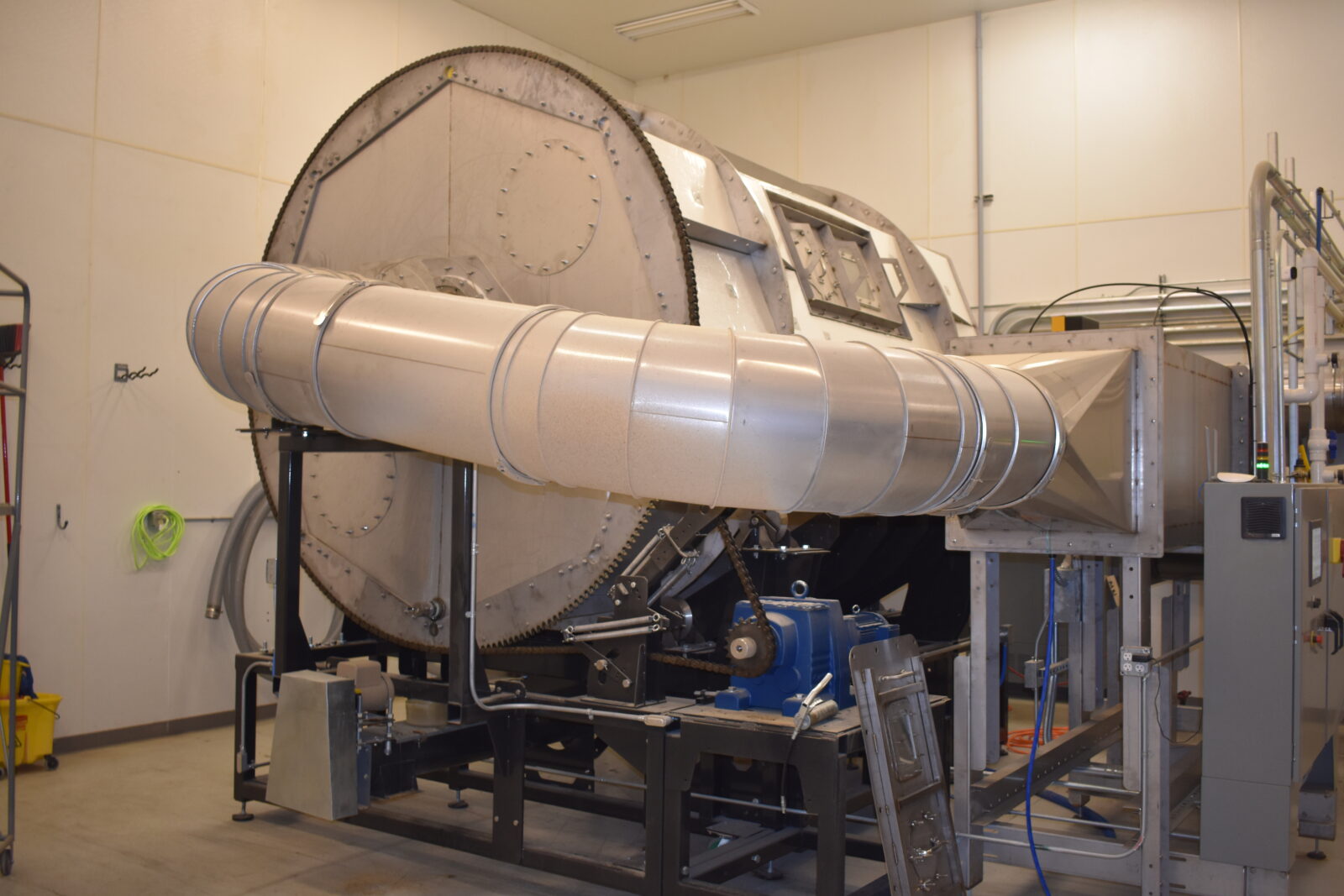

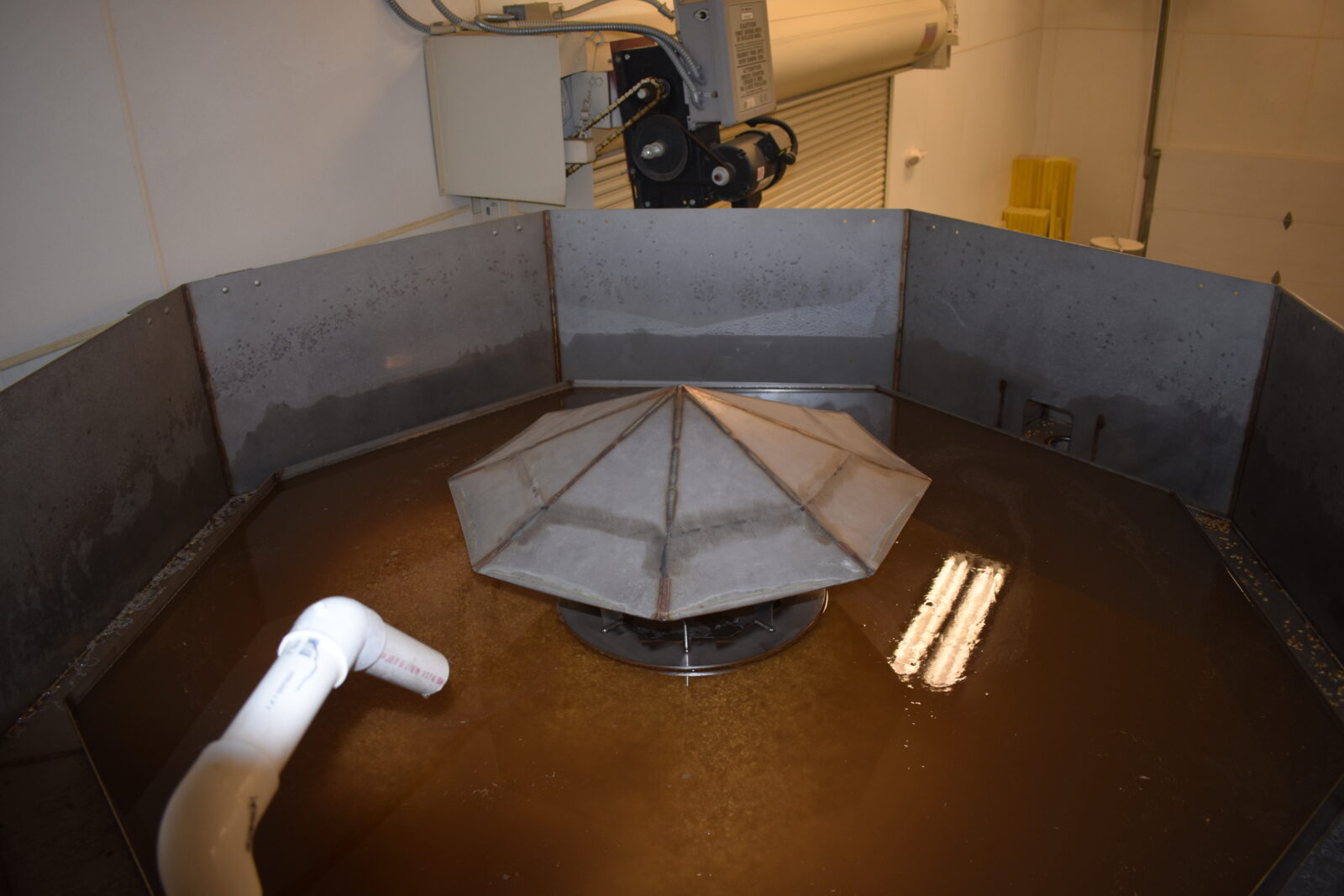

Wagner says the expansion would likely add a 25-ton malting drum to the current operation. “Our next step looks like we could put a 25-ton malting system together, which is still quite a bit smaller than what the big guys are doing,” said Wagner. “That allows us to be agile and do some interesting things with different types of grains while putting together a nice facility here in Crookston and hopefully employ a few folks. There is lots of research that could be done with a malting system of that size, which gets me really excited and we’ll still have the two-ton drums that will allow us to be flexible with the types of malt we produce.”

Key to Vertical Malt’s expansion plans will be the acres need to produce barley and other grains. Wagner wants to ensure Vertical Malt can maintain an intimate knowledge of the grain they are malting. “Should we move up to this 25-ton system, we will probably need 500-600 acres, maybe more than that,” said Wagner. “At this point in time we produce all of that ourselves, the expansion could lead to one or two other growers, that remains to be seen. We really want to keep that vertical part of Vertical Malt, so we know exactly where the grain is coming from, who its grown by to provide the traceability to the brewers. That’s very important to us to be able to demonstrate we know where the grain is coming from, what variety it was, what the crop year was like, what the growing conditions were, planting and harvest dates even.”

The expansion will allow Vertical Malt the flexibility to work with malting a wider variety of cereal grains. “We’ve been doing a fair bit of wheat in addition to barley and rye is one all of the distillers are really interested in for single-malt whiskey,” said Wagner. “Corn and rice and oats can all be malted as well. Any cereal grain can be malted, and they all impart a different type of flavor to the beverage. We’re looking at a lot of specialty grains and the varieties in each grain type. We get really jazzed about the research in that looking for varietal differences between barley, rye, and wheat, how protein effects flavor and to taste the difference between crop years.”

The initial expansion would be part of a possible multi-step expansion over several years. “That first 25-ton system is really just part one of a three-step expansion,” said Wagner. “We can add two or three additional 25-ton systems and reuse the equipment investment from system one. The steep tank gets reused, the kiln heater gets reused for systems two and three and possibly four. Hopefully, we’ll need to hire a half dozen people or more to work in operations, probably some people managing accounts.”

Wagner hopes the expansion will allow a greater impact on the region by Vertical Malt while staying off the radar of big malt houses. “The name of the game is trying to find that happy size where we can impact our region, but not show up too much on the radar of the big guys,” said Wagner. “We don’t want to go toe to toe with Cargill. We’re really catering to the small craft brewers, but that segment is really growing.”

Even an expansion of three 25-ton systems over a 10-year period would keep Vertical Malt on the smaller end as other systems are doing 80 to 120 tons in a batch and malting operations, such as Rahr Malting Company in Hillsboro, may include up to five malt houses. Wagner is working on the concept design for the facility that he believes will likely be located on the south end of town in the industrial area. “We’re probably looking the industrial part of town, maybe south of Titan or over by the water tower,” said Wagner. “There are a couple other spots that have been pointed out by the City of Crookston as well. We’d like to be either in or right next to Crookston as there are a lot of benefits to that as far as utilities and that kind of stuff. There is a lot to determine for the footprint about the flow of barley through the facility and storage that will be included in determining where we end up.”

An expansion would also add a few jobs to the market, although Wagner is protective of his product and says Vertical Malt will need to find the right people for the job. “I’m pretty protective of what we’ve built,” said Wagner. “It’s going to be a little while before I’m comfortable with too many people having to much say over what we do. It will have to be the right people with the same level of passion and commitment to the craft that we do.”